Sunday’s ending, and with it a fine and long weekend.

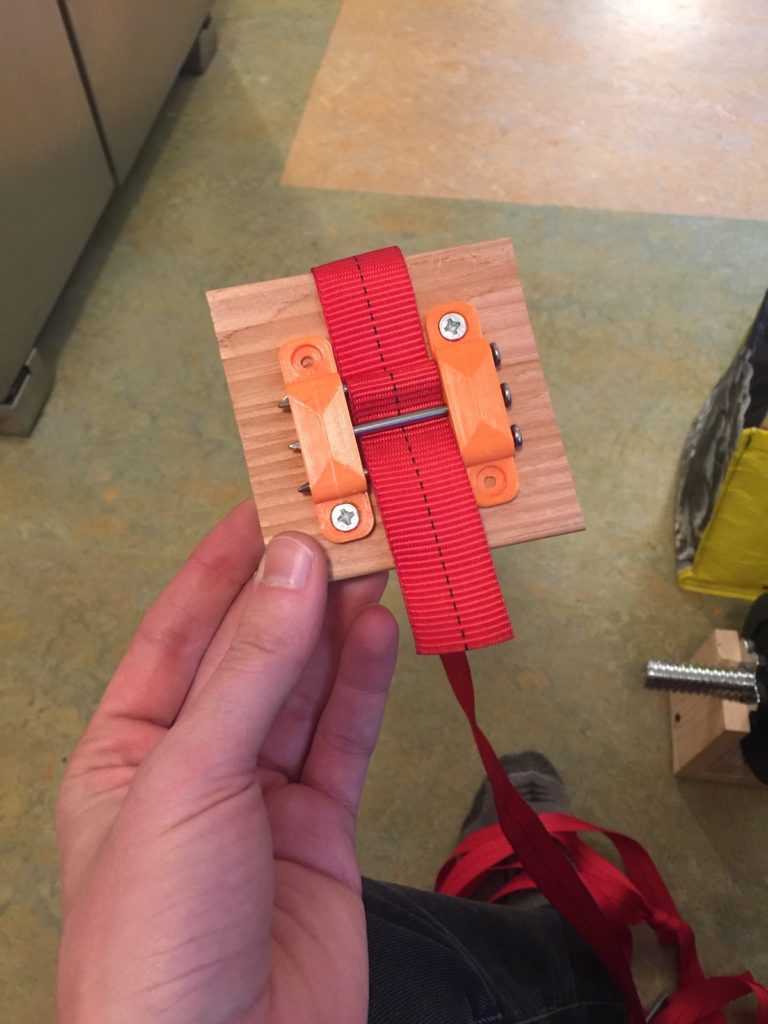

I spent the evening 3D printing some brackets for a new keyboard prototype I’m working up. I hatched the idea a good while back, but I haven’t turned back to it until now. I’ve been telling people about it, which is actually motivating. Then when people ask me if I’ve finished it yet, it provides the motivation I need to really get started.

If you walk around a dark house with only a laptop to light your face, I imagine you look like a tired ghost to any burglar who might be casing your place from the street.

I retired the second ladder I made for Zavian. It seems he lost interest in it before I was done making it. That’s ok. I’ll keep it stored in the basement in case he remembers it later. If not, I’ll dismantle it for the precious scrap wood. If my planning is accurate, Z will ask where it is one day after that.